Ford Mustang (1999-2004) Service Manual: Component Tests

Drive Belt Noise/Flutter

Drive belt chirp occurs due to pulley misalignment or excessive pulley runout. It can be the result of a damaged pulley or an incorrectly aligned pulley.

To correct, determine the area where the noise comes from. Check each of the pulleys in that area with a straightedge to the crankshaft pulley, looking for accessory pulleys out of position in the fore/aft direction or at an angle to the straightedge.

Drive belt squeal is an intermittent noise that occurs when the drive belt slips on a pulley during certain conditions, such as: engine start up, rapid engine acceleration, or A/C clutch engagement.

Drive belt squeal can occur:

- if any of the accessories are damaged, have a worn or damaged bearing,

internal torsional

resistance above normal. All accessories should be rotatable by hand in the

unloaded condition.

If not, inspect the accessory.

- if fluid gets on the drive belt. This includes power steering fluid, engine coolant, engine oil or air conditioning system lubricant. If fluid does get on the drive belt during service, clean the drive belt with soap and water and thoroughly rinse with clean water.

- NOTE: The drive belt tensioner arm should rotate freely without

binding.

if the drive belt is too long. A drive belt that is too long will allow the drive belt tensioner arm to go all the way to the arm travel stop under certain load conditions, which will release tension to the drive belt. If the drive belt tensioner indicator is outside the installation wear range window, install a new drive belt.

- if the drive belt tensioner is worn or damaged.

Belt Tension

NOTE: Drive belt tension is not adjustable.

The drive belt tensioner automatically adjusts drive belt tension.

Belt Tensioner, Automatic

Check the automatic drive belt tensioner:

1. With the engine off, check for correct drive belt routing; refer to Accessory Drive. Repair as necessary.

2. Rotate the drive belt tensioner and check for a binding or frozen condition. Install new components as necessary.

Drive Belt Misalignment

CAUTION: Incorrect drive belt installation will cause excessive drive belt wear and may cause the drive belt to come off the drive pulleys.

Non-standard drive belts may track differently or incorrectly. If a drive belt tracks incorrectly, install it with an original equipment drive belt to avoid performance failure or loss of drive belt.

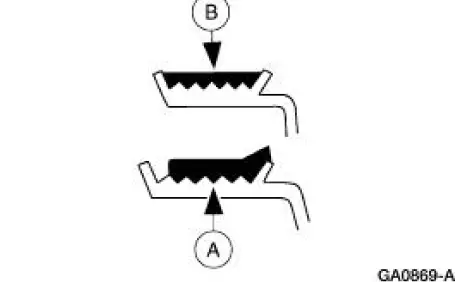

With the engine running, check drive belt tracking. If the (A) edge of the drive belt rides beyond the edge of the pulleys, noise and premature wear may occur. Make sure the (B) drive belt rides correctly on the pulley. If a drive belt tracking condition exists, proceed with the following:

- Visually check the drive belt tensioner for damage, especially the

mounting pad surface. If the

drive belt tensioner is not installed correctly, the mounting surface pad

will be out of position.

This will result in chirp and squeal noises.

- With the engine running, visually observe the grooves in the pulleys (not the pulley flanges or the pulley forward faces) for excessive wobble. Install new components as necessary.

- Check all accessories, mounting brackets and the drive belt tensioner for any interference that would prevent the component from mounting correctly. Correct any interference condition and recheck the drive belt tracking.

- Tighten all accessories, mounting brackets, and drive belt tensioner retaining hardware to specification. Recheck the drive belt tracking.

Inspection and Verification

Inspection and Verification

1. Verify customer concern by running the engine.

2. Inspect the drive belt for chunking, fraying and wear.

3. Check the drive belt for correct routing.

Drive Belt Cracking/Chunking/Wear

V Ribbed Se ...

Accessory Drive Belt - 3.8L

Accessory Drive Belt - 3.8L

Removal and Installation

1. Rotate the drive belt tensioner counterclockwise and remove the drive

belt.

2. NOTE: Make sure the drive belt is correctly installed on each

pulley.

To install, reverse ...

Other materials:

Torque Converter Turbine to Pump Stator Interference

Check

1. NOTE: Front pump support may remain in front pump support and gear

during this test.

Position the torque converter with the pump drive up.

2. Install the front pump support to engage the mating splines of the front

pump support shaft on

the torque convert ...

Evaporator Core Housing

Disassembly

1. Remove the evaporator core housing. For additional information, refer to

Evaporator Core

Housing in this section.

2. Remove the foam weather seal.

3. Remove the screws and remove the heater core.

4. Remove the screws and remove the A/C rec ...

Piston - Pin Diameter

1. Measure the piston pin diameter in two directions at the points shown.

Verify the diameter is

within specification.

Refer to the appropriate section in Group for the procedure.

If out of specification, install new components as necessary. Refer

...