Ford Mustang (1999-2004) Service Manual: Crankshaft Pulley

Special Tool(s)

|

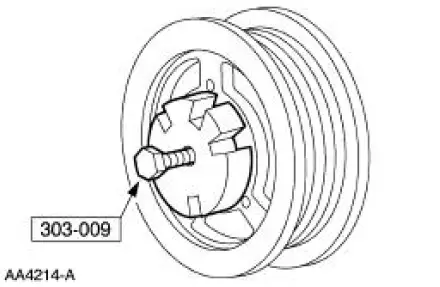

Remover, Crankshaft Vibration Damper 303-009 (T58P-6316-D) |

|

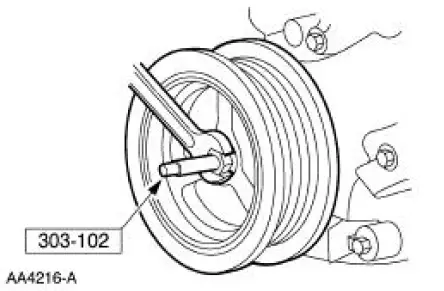

Installer, Crankshaft Vibration Damper 303-102 (T74P-6316-B) |

Material

| Item | Specification |

| Silicone Gasket and Sealant F7AZ-19554-EA or equivalent | WSE-M4G323-A4 |

Removal

1. Remove the drive belt. For additional information, refer to Section.

2. Raise and support the vehicle. For additional information, refer to Section.

3. Remove the bolt.

4. Using the special tool, remove the crankshaft pulley (6312).

Installation

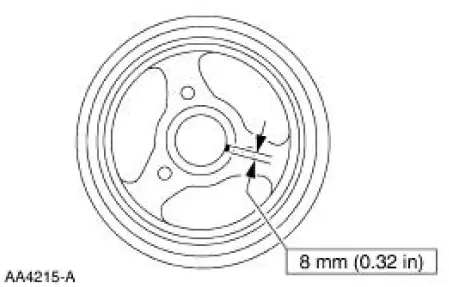

1. NOTE: The crankshaft pulley must be installed within four minutes of applying the sealant.

Apply sealant to the woodruff key slot on the crankshaft pulley.

2. Using the special tool, install the crankshaft pulley.

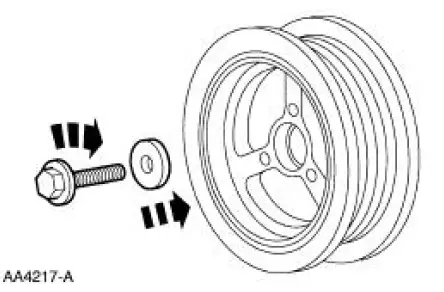

3. Install the washer and the bolt. Tighten the bolt in four stages.

- Stage 1: Tighten the bolt to 90 Nm (66 lb-ft).

- Stage 2: Loosen the bolt one full turn.

- Stage 3: Tighten the bolt to 50 Nm (37 lb-ft).

- Stage 4: Tighten the bolt an additional 90 degrees.

4. Lower the vehicle.

5. Install the drive belt. For additional information, refer to Section.

Valve Cover LH

Valve Cover LH

Material

Item

Specification

Silicone Gasket and Sealant

F7AZ-19554-EA or equivalent

WSE-M4G323-A4

Removal and Installation

1. Position the oil level tube (6754) out of the way.

2 ...

Crankshaft Front Oil Seal

Crankshaft Front Oil Seal

Special Tool(s)

Crankshaft Seal

Installer/Aligner

303-335 (T88T-6701-A)

Front Cover Seal Remover

303-107 (T74P-6700-A)

Crankshaft Seal Installer

303-635

...

Other materials:

Rear Drive Axle and Differential

The differential housing (4010) consists of a cast aluminum housing and

a cast aluminum

differential housing cover (4033). The differential housing cover uses

silicone sealant as a

gasket.

The hypoid-design gearset consists of a 8.8-inch ...

Fog Lamps

Refer to Wiring Diagrams Cell 86 , Fog Lamps for schematic and connector

information.

Special Tool(s)

73 III Automotive Meter or

equivalent

105-R0057

Principles of Operation

The fog lamps will only illuminate when the low beam or parking l ...

Transmission (DISASSEMBLY)

Special Tool(s)

Slide Hammer

100-001 (T50T-100-A)

Holding Fixture, Transmission

307-003 (T57L-500-B)

Slide Hammer

307-005 (T59L-100-B)

Remover, Transmission Fluid

Seal

307-048 (T74P-77248-A)

...